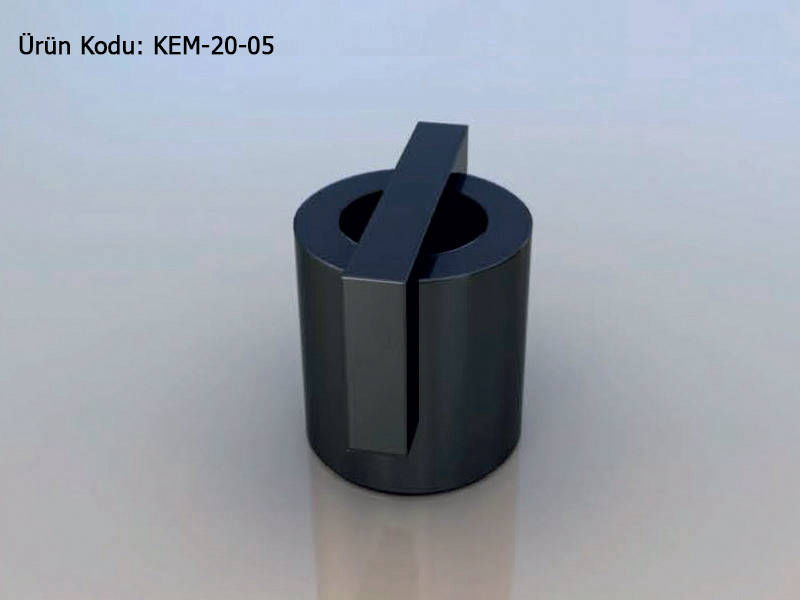

DM-KEM 20 Cement injection machine with boiler, used for injection pumping liquid calcium based chemicals with high density and low viscosity such as cement, plaster mixtures, stucco and grout in vertical or horizontal positions at high pressures. It is a perfect solution for the reparation stabilization and strengthening of the constructions such as bridges, buildings and dams; and also for operations such as anchorage filling, cement flooring and grouting, pumping cement, plaster, lime or other solutions towards or upwards construction areas, clay pumping or transferring, tunneling, precast unit productions etc. With its integral mixer and a section for water intake, it is easy to prepare the mixture with the proportions you want. The mixture in the boiler is transferred to the operation area by a hose; and according to the needs of the customer, the nozzles of the hose can easily be changed with different ones. All the parts that were in contact with the mixture can be washed afterwards and they all are corrosion resistant. Double sealed water and dust resistant electrical panel provides safety to the operator, which is very crucial at worksite environments. Phase sequence protection, high and low voltage protection, high current flow protection and thermal protection are some of the many other safety features. Due to the ease of spare part replacement, it doesn’t require any qualified personnel or doesn’t need any calibration or adjustment to be done afterwards. It can be used in low ceilinged and narrow spaces because of its compact design. With high quality spare parts at affordable prices, KEM 20 is a must-have in your equipment pool.